In general tighter tolerance components or rigid.

O ring cross section tolerance.

Dimensional tolerances for all metric o rings offered by global o ring and seal are in accordance with iso 3601 1b.

Manufacturers of encapsulated o rings and industrial gaskets.

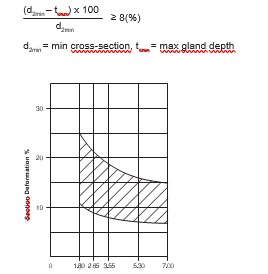

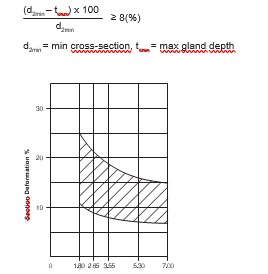

The difference between the original o ring cross section and the final o ring cross section once installed is known as the compression squeeze.

Find the right o ring tolerance for your application and easily order online today from the world s largest o ring inventory network.

O ring size chart as568 standard o ring sizes find as568 o ring standard sizes by cross section inside diameter and outside diameter in our o ring size chart and separate o ring tolerance chart.

You can select your tolerance range in the store.

Our tolerances are only meant to serve as a guide.

0 08 mm and shall not cause deviation from the nominal section of the o ring in excess of the drawing tolerances i e.

When the cross sectional diameter is on its lower limit no flat ting is permissible.

The main advantages of larger cross section o rings include being less prone to compression set less volume swell in liquid based on percentage basis and allows for larger tolerance while maintaining an acceptable compression squeeze and compression ratio over full stack up range.

An o ring is a solid rubber seal shaped like a doughnut or torus.

O ring tolerances for cross section and inside diameter.

Axial dimensions of an o ring shall not exceed a depth of 003 in.

The o ring tolerances outlined in the charts below reference general purpose o rings and x rings.

Nominal cross section o rings.

For non standard o rings however there is no industry standard for this several dimensional specifications have to be taken into consideration.

Please contact us if you are looking for a size not shown in the 5 32 group.

Diameters cross sections tolerances and size identification code.

Until now o ring standards have left a gap between the 1 8 and 3 16 nominal cross sections.

Select a size to buy standard and custom o rings from the world s largest inventory network or custom orders can be made within a few weeks typically without tooling fees.

For recommended o ring c s squeeze values please refer to page 11 12.

To leaks caused by spiral failure of the o ring.

Non continuous flats shall be blended out smoothly.

In de signing this new group of o rings we left spacing in the part numbers to allow us to add additional sizes should they be required.